In this white paper package design, reflow profiles, and solder paste chemistry are discussed in the form of application studies.

Vapor Phase Reflow Soldering Helps Eliminate Manufacturability Challenges

Smaller products translate to denser printed circuit board (PCB) layouts, smaller, more complex components and inaccessible

interconnections.

Vapor phase soldering can improve solder paste wetting and SIR results.

Vapor phase reflow is a mature process that solves the issue of preserving small discrete components on large thermal mass assemblies. It has shown in this testing, and previously reported work to afford superior wetting to convection oven reflow.

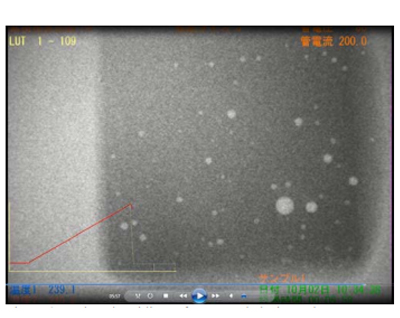

Use Of 3 Thermocouples To Verify A Printed Circuit Board Profile During The Reflow Operation

This paper presents the results of an initial study to determine if the use of only 3 thermocouples can be utilized to verify a PCB’s profile during the reflow operation…

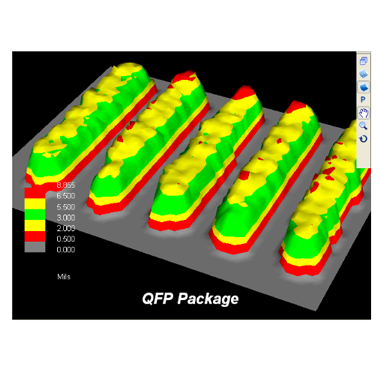

3D Solder Paste Inspection, a Yield Improvement Strategy that Works

Learn to understand what your yields are, how they are affected by the printing process, how to measure them…

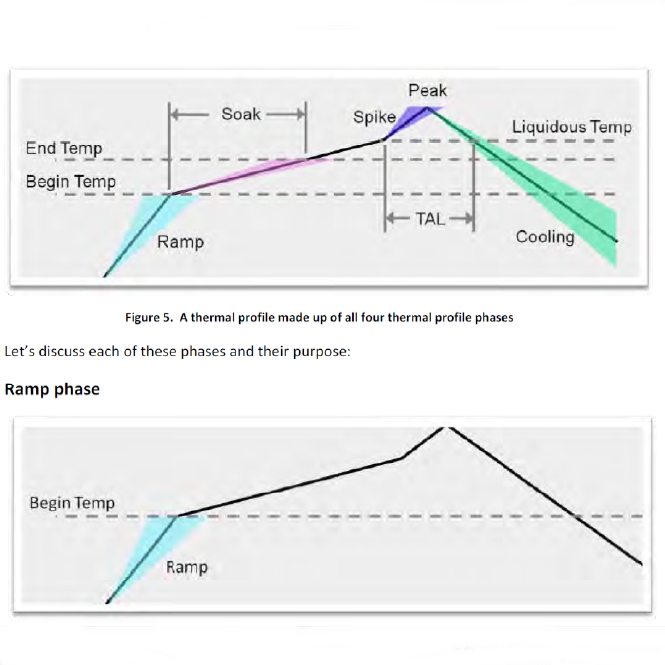

The Basics of Reflow Soldering

The basics of reflow soldering, a thermal process designed to melt solder paste which has been placed on the…

Thermocouple attachment methods for solder paste reflow soldering

This article discusses the different methods for attaching thermocouples, and how to implement them for best results…

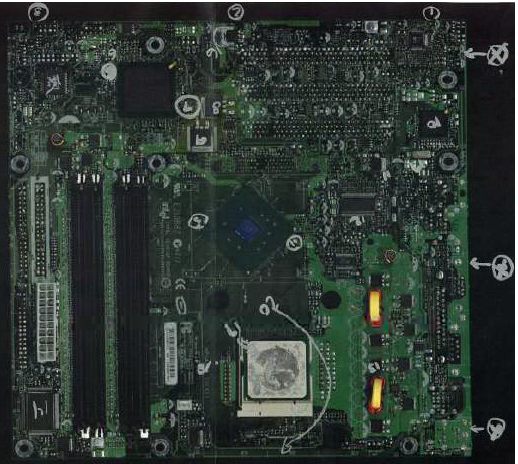

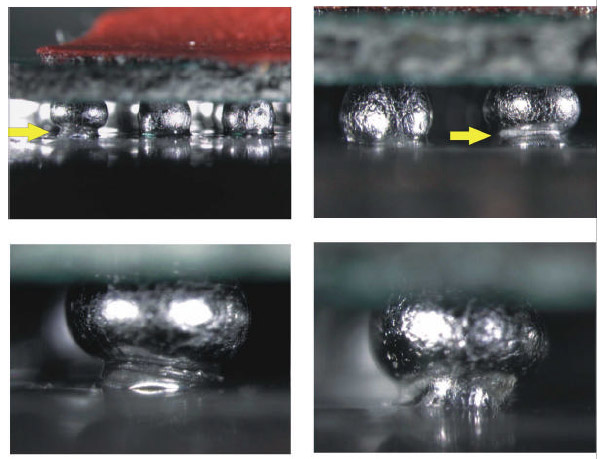

Head in pillow defect of BGA package case study

This is a report of findings concerning an investigation of the three 492 ball BGA’s and one bare motherboard that were…